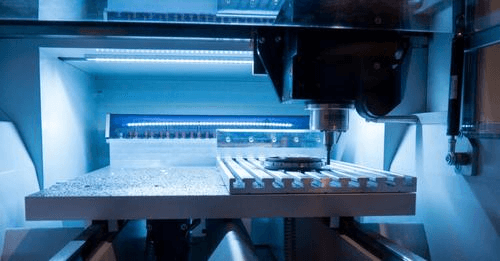

Reach Robotics recently added a CNC mill to their in-house manufacturing facilities. This article details how the mill will improve the prototyping process and how a CNC mill works.

Reach Robotics’s new CNC mill will enable manufacturing parts in-house with higher complexity and in less time than making the same part with a classic mill or lathe. This is particularly useful in R&D prototyping for our electric manipulators. Simple parts can now be made on the 3-axis milling machine, reducing lead time by weeks and costs. Corrections and modifications can be made to complex components such as manipulator motor components and the housings, allowing quicker prototyping and cost reduction.

The CNC mill has significantly increased the capacity of Reach Robotics’s in-house machining, including the ability to;

– Machine a complex pocket in a part/billet

– Machine a cylinder or a bore in a non-cylindrical part

– Drill and tap a complex pattern of holes

– Chamfer sharp edges automatically

– Machine threads

All with the addition of automatic dimension accuracy of the result.[AR3]

What is a CNC Mill, and how does it work?

A CNC (Computer Numerical Control) mill is a machine engineered to mechanically cut away at a workpiece (generally a metallic or plastic billet) into the desired shape to produce a physical part. A computer programs the machine to move a cutting tool following a path that can be very complex. CNC mills are highly accurate and repeatable, which allows them to machine multiple high-tolerance parts in a short period.

A CNC moves a cutting tool attached to the spindle along or around a set of defined axes. The spindle spins at high RPM, providing the cutting power to the tool. The more axes the machine has, the more complex a part can be machined. However, path programming also becomes more difficult.

To manufacture a part, first, an engineer creates a 3D model of the part to be manufactured in CAD software. This model goes to the CNC operator, who will generate a simulated path for cutting material off the stock. These paths are exported as g-code, which the CNC can understand, telling the machine exactly where to go, how fast, and control other parameters such as coolant. Once the paths have been generated and the stock loaded into the machine, it is simply a matter of running the paths and monitoring the machine.

What training is required to use a CNC machine?

Machining is a complicated process requiring specific training on the machine, its interface, and many hours of practice to hone one’s relevant skills. However, it takes considerable time to understand different cutting tools, cutting operations, and work-holding techniques. Over time, this will increase the production rate and the quality of the parts manufactured in-house.

What are the advantages of a CNC Mill over a manually operated Mill?

A CNC mill uses computer-aided manufacturing to remove material from a block of stock to produce a physical part. CNC mills are highly accurate and repeatable, which allows them to machine multiple high-tolerance parts in a short period. CNC mills can translate 3D drawings into a custom part in a highly accurate, repeatable way. CNC mills are highly accurate and faster than manually operated mills.

What is Computer-Aided Manufacturing (CAM)?

CAM (Computer-Aided Manufacturing) is the transition step between the Computer Aided Drawing (CAD – the part’s 3D file) and the CNC mill. You can picture it like a translation of the 3D file into the language (“G-code”) the CNC needs to machine said mechanical part. This is where the Operator will program all the different operations the machine will take to obtain the final product.

What is the difference between a 3-axis, 4-axis or 5-axis CNC machine?

Reach Robotics’s CNC mill is a 3-axis CNC mill that can move a tool along the three dimensions of space: x, y, and z (front-back, right-left, up-down). On top of those capabilities, a machine with more than 3-axis can rotate the tool around one of these axes to machine a pocket in part at an angle, for example.

How will Reach Robotics use the CNC Machine?

Reach Robotics engineers will use the CNC machine to rapidly prototype and validate new designs for internal and custom client projects. As the R&D team invests time in machining, it will cause mechanical engineers to be more aware of manufacturing constraints during the part design process. For example, which part features are possible and efficient modelling of complex components. This will lead to simpler parts which mean more precise dimensions and consistent quality.