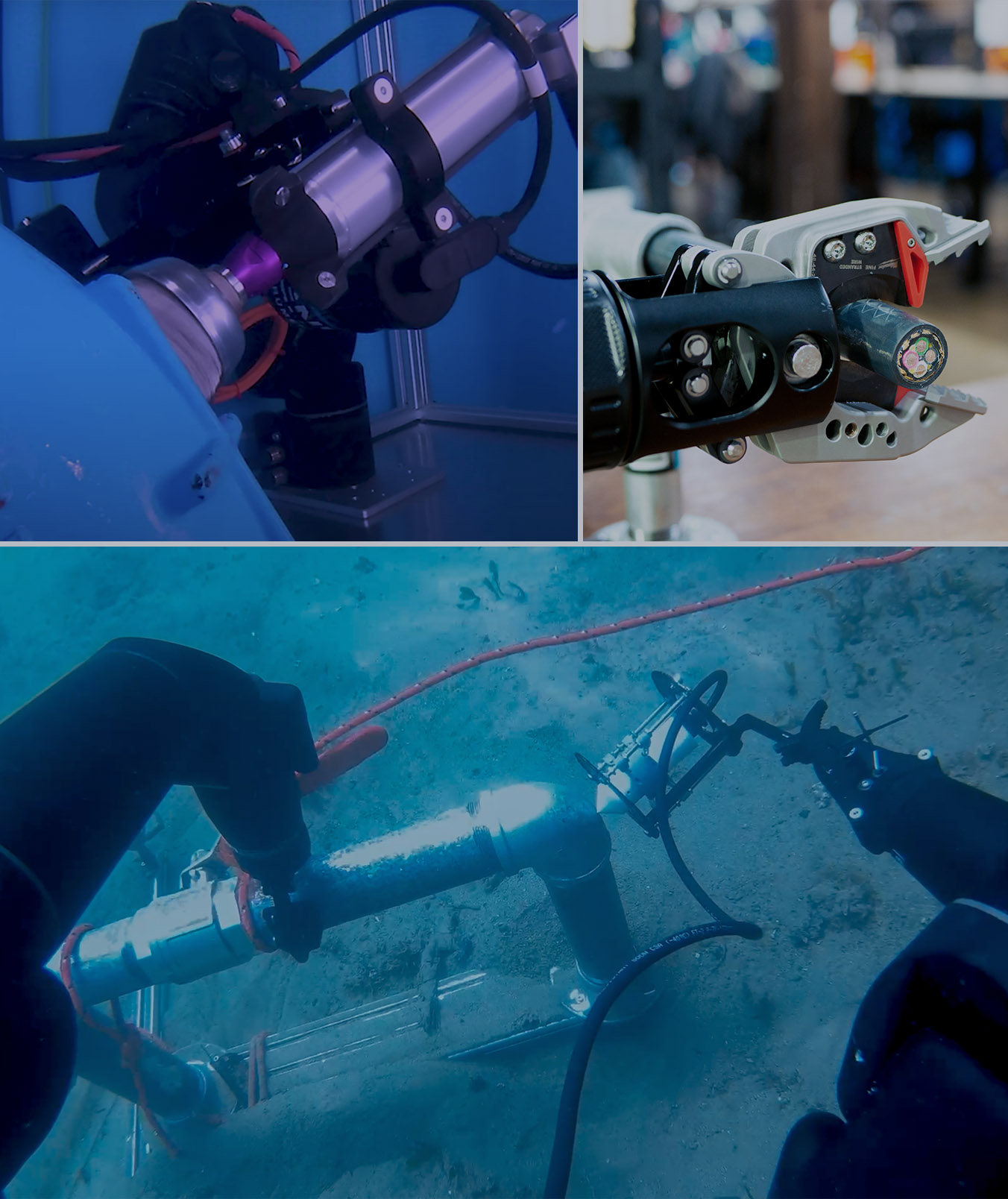

Inspection-class ROVs are portable observation vehicles typically used for underwater intervention and maintenance activities. The ROVs propensity to integrate with a variety of external tooling including robotic manipulators, cameras, sonars and measurement tools allow for the development of highly capable and customisable robotic systems.

ROVs configured with robotic manipulators are of particular value to Oil & Gas and Offshore Energy sectors for operation and maintenance (O&M) activity. Offering diverse use-cases, a low logistics footprint and greater operational efficiency, these robotic systems offer capabilities previously only achieved by human divers in high-risk operations. The following list outlines O&M tasks that can be carried out with Reach Robotics manipulator arms, integrated on inspection-class vehicles.

Cleaning Surfaces with Brush or Blaster

Cleaning capabilities for offshore rigs and pipes is maximised by affixing third-party brushes and blasters to our advanced robotic manipulators. The Reach Bravo series features continuous 360° rotating joints which allow for continuous contact on a surface, while applied pressure can be customised and maintained using the Force Torque Sensor module.

Cutting Cables/Rope

Cutting rope, soft-line and copper electrical cables up to 25mm diameter is simple with the Bravo Cutter end-effector. Working together with the Bravo manipulators powerful linear axis, the Cutter jaw is a strong and capable intervention tool for clearing tangled lines and other activity.

Inspecting Surfaces with Camera or Probe

Offshore structures require regular observation and monitoring for corrosion or damage. A variety of third-party cameras, probes and sensors can be attached to our robotic arms to assess integrity of underwater infrastructure, enabling direct visual feedback and accurate readings.

Recover or Place Objects

A large variety of grippers (end effectors) are available in different shapes and sizes to place and recover objects in salvage or maintenance operations. ROV operators can easily interchange between end effector tools with very little down-time to efficiently meet their specific task requirements and deadlines.

Rugged Lifting & Movement of Obstacles

Our robotic arms are designed and built to withstand harsh environments while wielding heavy or imbalanced objects. The Reach Bravo can lift and manoeuvre up to 10kg at full extension in unpredictable subsea conditions. It features in-built compliance to external loads, protecting against damaging or extraneous force.

Attach Industrial Hooks

Reliably lift, manoeuvre and place industrial hooks, carabiners and shackles with high grip-strength at the end effector, proven to 1000+N. With high-accuracy joint positioning, conquering precision-based tasks underwater is more achievable.

Turn Industry-Standard Valves

Turn industry standard ball and globe valves using the Reach Bravo’s powerful kinematics engine and continuous rotate feature. Our robotic arms feature high accuracy join positioning, a variety of control methods and high dexterity for remote operation of taps and valves.

Reach Robotics manipulators are proven on leading inspection-class ROVs and are favoured by operators seeking reliable solutions in harsh environments.