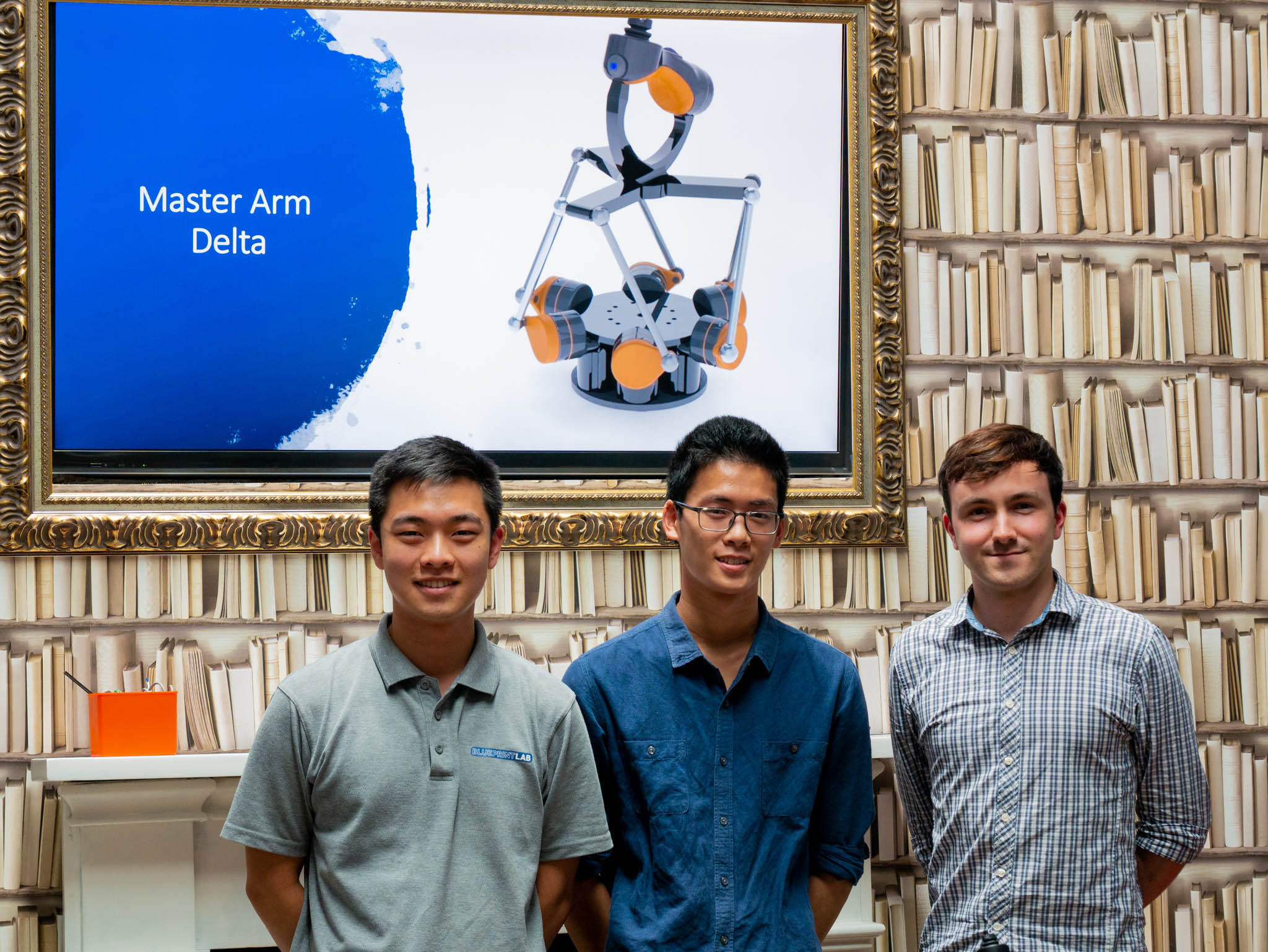

For the past 12 weeks Reach Robotics interns Cameron Chan, Daniel Jiang and Nelson Reynolds-Walsh have been developing a prototype human-machine interface (HMI) controller to pair with Blueprint Lab manipulators. At the culmination of their internship, they presented their design – the Master Arm Delta. The presentation rounds out their summer internship at Blueprint Lab.

The aim of the project was to develop a 6 Degree of Freedom (6DOF) controller, capable of mimicking Velocity (°/s) and Cartesian (x, y, z, ROLL, PITCH, YAW) movements of the user. This was proposed as an alternative to the Blueprint Lab Master Arm.

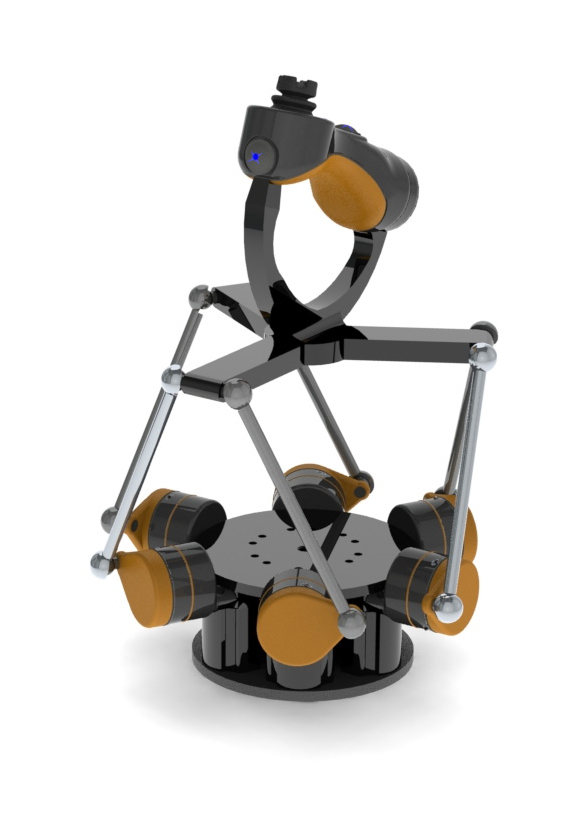

The Master Arm Delta is based on a Stewart Platform with a base ring of motors engaging the joints of a robotic manipulator. The new technology simplifies user experience where operators focus on a single objective – the end-effector position, while all other joint mechanics are automated to meet the end-effector’s specifications. This enables control with greater efficiency and accuracy as less time is spent manually aligning and adjusting individual manipulator joints’ motion, position, and rotation.

Nelson outlined the highlights of his summer internship;

“- The opportunity to lead a mechanical design project from initial design ideation to producing a functioning prototype of an end-effector controller (all with the backing and resources provided by Reach Robotics’s Research and Development team).

– Experience with outsourcing precision machining, company engineering data management systems and other high level engineering practices.

– Experience with industry standard engineering practices, such as instructing precision machined parts and exposure to mechanical design Product Data Management (PDM) systems.

– The opportunity to contribute mechanical design solutions to assist the continuous improvement of the company’s production line and its efficiency.

– Applied advanced theoretical concepts in a professional setting, such as forward kinematic control and Finite Element Analysis (FEA).”

On evaluation they found that the Master Arm Delta achieved a large range of motion, higher resolution of control, effective force feedback, an ergonomic design, and utilised existing Reach Robotics components. Areas of future improvement included the large footprint and the intricacy of the design.

From all the team at Reach Robotics, it was a pleasure to host you, Nelson, Cameron and Daniel and we were very impressed with the way you rapidly brought an idea to reality. We wish you all the best in what look to be very promising careers.