Subsea intervention has traditionally been undertaken by large and expensive Underwater Vehicle Manipulator Systems (UVMS). Though extremely capable, these work-class platforms require teams of highly-skilled operators and extensive logistics to manage, driving consumers in both commercial and research sectors to seek smaller portable ROV alternatives. The more compact UVMS are less expensive and require far less operator training and support equipment, however their reduced size corresponds with reduced areas of capability – many of which are being explored and overcome by researchers around the world.

Wilhelm Marais (Wil) is a recent PhD graduate from the Australian Centre for Field Robotics (ACFR) and has a long association with Reach Robotics dating back to 2017. Wil was among our first interns, working on the development and verification of our early manipulator technology and has since been a critical member of our R&D team. Over the past four years, his PhD work has centred on three key areas of reduced capability associated with portable UVMS:

- Increased susceptibility to disturbances from the environment

- Reduced operational time due to battery constraints

- Reduced ability to exert forces and torques during physical intervention

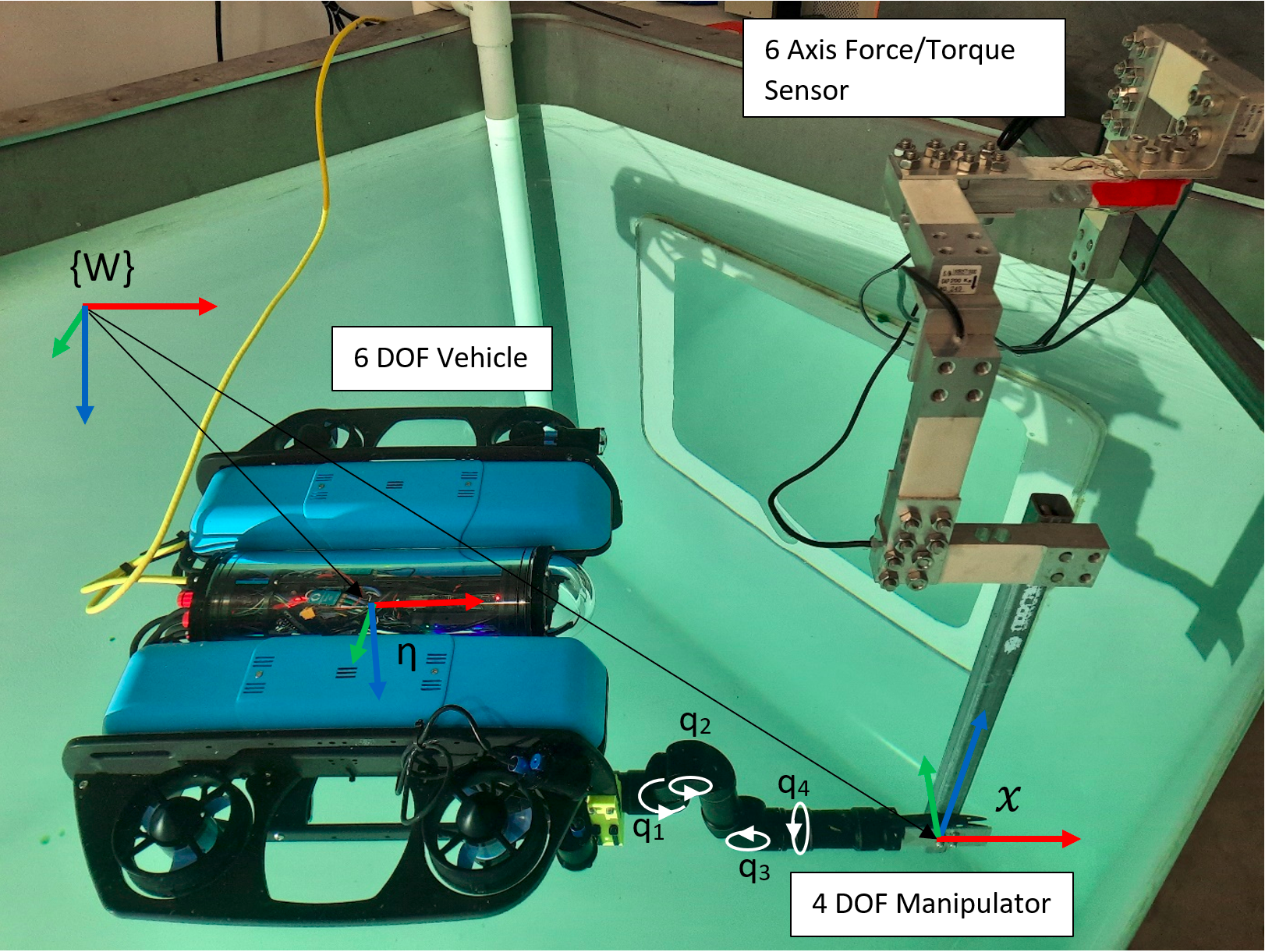

As Wil elaborates in his thesis, addressing these shortcomings requires exploiting ‘kinematic redundancies’ where the number of degrees of freedom possessed by the system exceeds the minimum number required to complete a task. Utilising kinematic redundancy requires the ROV and manipulator to work simultaneously, exploiting all available degrees of freedom to position the end effector of the manipulator, while also maximising the capabilities of the system.

Addressing the areas of reduced capability using existing solutions for kinematic redundancy is complicated by the large number of variables involved, leading to inefficient and suboptimal solutions. Wil’s work proposes methods to improve the efficiency of solving these problems by producing flexible algorithms to maximise the performance of any UVMS, with specific regard to the three key areas of reduced capability. Using both a high fidelity simulation environment and hardware experiments using an Alpha 5 manipulator, the work demonstrates how the proposed methods can improve the system’s ability to react to disturbances, reduce power consumption, and maximise the amount of force or torque that can be exerted.

Although implementing these methods in an intuitive user interface still requires a lot of work, the promising results suggest that many subsea intervention tasks currently performed by work class vehicles may be achievable using smaller and more portable systems.

Reach Robotics is proud to continue working closely with Wil to further explore the potential of portable UVMS. Alongside multiplying the capability, accuracy and efficiency of underwater operations, smaller intervention systems offer reduced costs, simplified logistics and minimised training requirements to subsea industries. If you’re interested in learning more about Wil’s research and our advanced manipulation systems, please get in touch today.

info@reachrobotics.com