Force and Torque Sensors and their use in Robotic Manipulation

Force is an influence that can change the motion of an object.

Torque is the rotational equivalent of linear force.

The world is subject to motion and control; every applied force has a certain output or result. With that being the case, humans consciously or subconsciously use controlled force for every action, even for the most basic tasks. This knowledge enables us to interact with the world effectively. For every task we perform, from walking to painting with a brush, scrubbing the dishes, or picking up a heavy or delicate object, we moderate our actions by adjusting our strength accordingly.

Implementing robotic arm solutions that replicate human sensitivity requires an identical sense of human force and torque. With this information, robotic arms can effectively recreate the human motion of picking and placing objects, and carry out inspection and intervention tasks such as Non-Destructive Testing (NDT), painting, welding, cleaning, and interacting with control panels, especially in cases where visual information and depth perception is limited.

Two tasks showcase the importance of force and torque in robotics:

- What’s required to design a robotic manipulator capable of delicately picking up an egg without breaking it yet still being able to hold onto it securely?

- What would include to build a robotic manipulator that can accurately move a welding torch along a weld seam while ensuring it stays in contact with the object without damaging or penetrating it?

Force/Torque Sensors and their Implementation in Robotic Arms

There are three main types of force and torque sensors:

Pure Force Sensors:

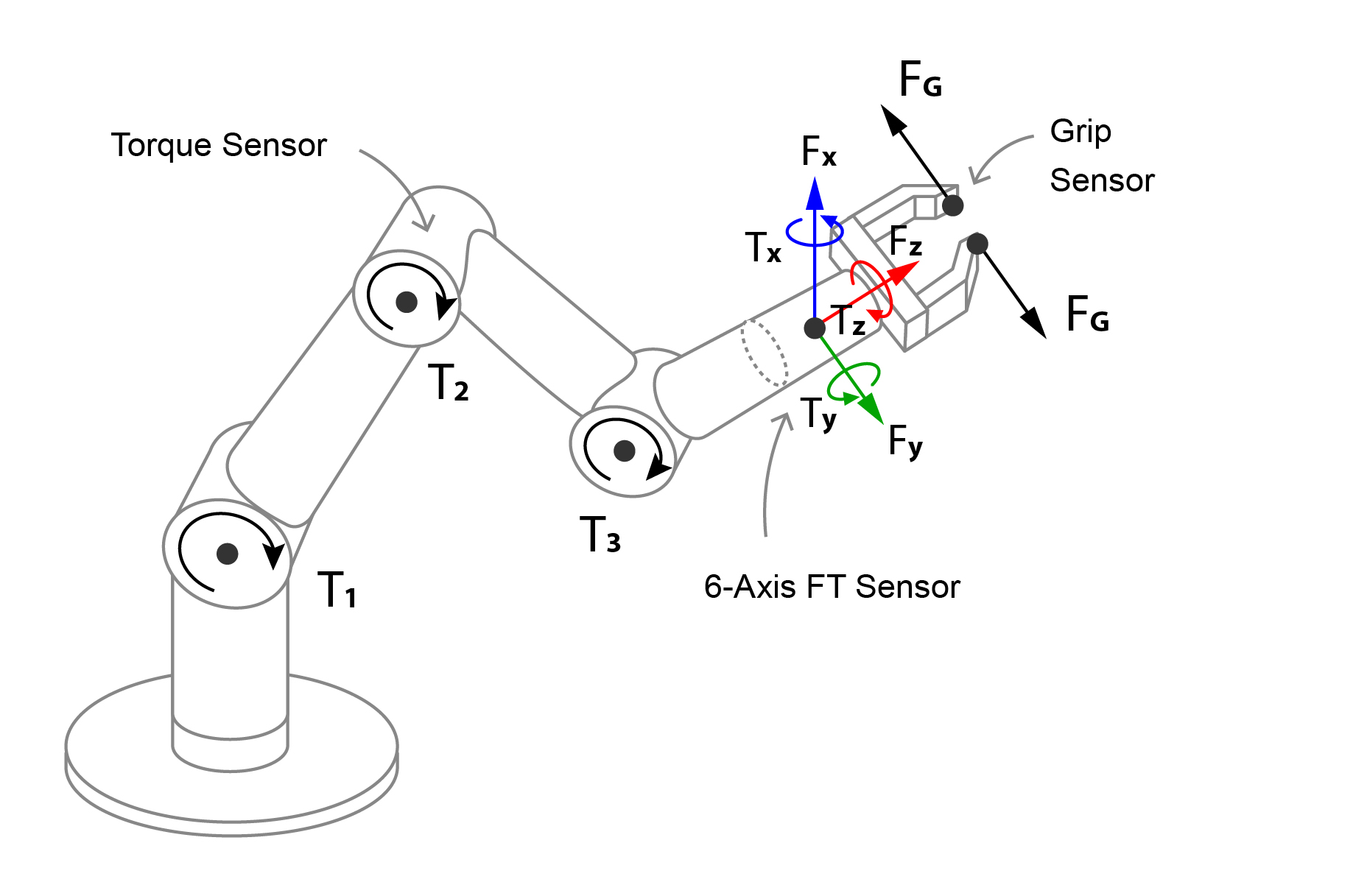

These are mainly installed within the gripper or ‘fingers’ of a robotic arm to measure grip force. They are often simple and provide a force measurement in only one axes, however more advanced solutions provide 3D force (multiple axes) and slip information, such as that provided by Contactile.

Figure 1 – The PapillArray Grip 3D Force Sensor from Contactile

Pure Torque Sensors:

These are mainly installed within the revolute joints of a robotic arm to enable a sense of the torque being applied or experienced by that section of a robotic arm. This is very important for moderating a robotic arms input/command current as well as enabling compliance in the event of large external torques being applied.

Figure 2 – A Pure Torque Sensor from Forsentek

6-Axis Combined Force/Torque (FT) Sensors:

These sensors combine the ability to sense force and torque and can therefore measure tensile and compression forces as well as elastic deformations and rotational forces (torques) around each of the three axes. (3 x Force and 2 x Torque around each axis = ‘6 Axis’) These FT sensors are often installed in the final ‘limb’ or a robotic arm just before the jaw or ‘End of Arm Tooling’ (EOAT), such as in Reach Robotics’ Bravo FT sensor installation.

Figure 3 – A Combined 6-Axis FT Sensor from OnRobot

Combining these types of sensors, we could visualize an ‘ideal’ robotic arm (from a FT perspective) as looking something like this:

What applications do FT Sensors enable?

The list here could be long. For starters, almost all the applications listed here would benefit from additional information provided by Force and Torque sensors. Perhaps the best examples of ‘disruptive’ applications for robotic arms with force torque sensors are:

- The introduction of robotic arms for factory automation (welding, pick and place, painting etc.)

- The introduction of robotic arms for automated inspection and intervention in the offshore and onshore energy sectors

Whilst the first has come to be accepted and taken for granted, the second application is only emerging more recently, given the additional complexities of operating in harsh and unpredictable or ‘unstructured’ environments. Various clients of Reach Robotics, including research institutes, are working to solve this problem with the Reach Bravo robotic arm equipped with a 6-axis wrist FT sensor. A great example of this can be seen in the video below.

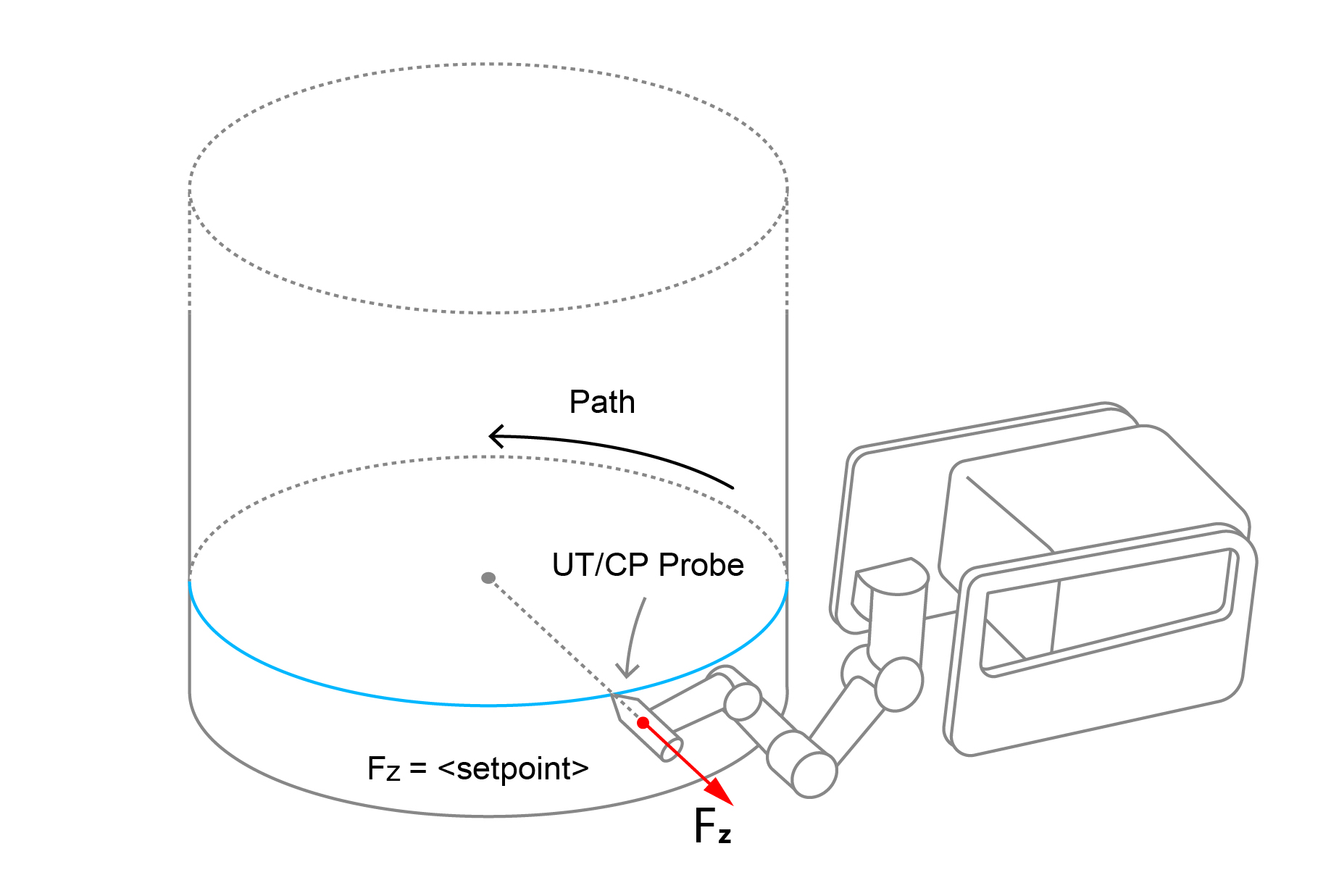

To get more specific, one application of a robotic arm equipped with an FT sensor is scanning along a surface with a Non-Destructive Testing (NDT) probe. In the offshore energy sector, it is often important to measure a steel structure to detect any cracking, corrosion, or the condition of protective surface finishes. This article describes NDT a little more.

To scan along a surface using only visual feedback (i.e., looking at a video feed) is extremely difficult. Even with high-definition video quality, lack of depth perception can make it difficult to determine the precise relative positions of the objects. For example, if an FT sensor is present, automated solutions to this problem can be implemented whereby the robotic arm is set to maintain a certain force, say 1N, into the structure. As the operator (or autonomous control algorithm) moves the probe along the surface, the robotic arm modifies its joint positions and velocities to maintain that 1N force into the structure, regardless of any relative motion or disturbances.

Can’t current measurements in each motor be used as an analog to force/torque?

Sometimes. Current is proportional to the torque output of the motor. It is then transferred through a gearbox that increases the torque by the gearing ratio multiplied by the efficiency. When an external force is exerted on the arm only the reaction of the motor can be measured. The reaction is a function of the closed-loop control, and therefore, the motor response is dependent on the type of controller, the gains applied, and the resulting position or velocity error due to load. Another factor is that the gearbox accommodates for some proportion of the load through friction. Friction is a complex property to characterize and makes estimating the true torque load inaccurate. All that said, as a general concept, current can be used to estimate the driving output torque, such as when lifting a weight but is inaccurate as a measure of disturbance loads such as someone pushing on the manipulator.

Getting Specific – What are the specifications of the Reach Robotics FT Sensor Upgrade?

Readers who are interested specifically in the Reach Bravo FT upgrade, can be found here.

We offer the Reach Bravo FT sensor upgrade with the initial purchase or as a retrofit upgrade for existing customers.

Check out the Reach Bravo for more information on features and specifications.

Work with us

Speak with us on your project requirements.