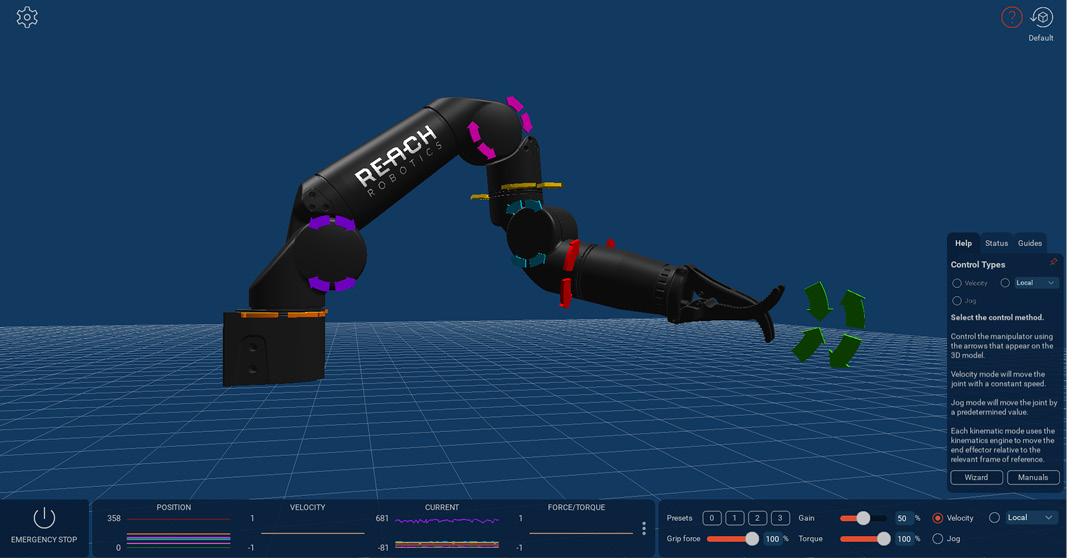

Reliable, remote operation is a key feature of Reach Robotics’ manipulator technology. Since the launch of our flagship ‘Reach Alpha’ robotic arm series, we’ve provided advanced custom control solutions for operators to make the most of their manipulators. Our Reach Control software is an intuitive human-machine interface (HMI), custom designed to work with our manipulators and master arm controllers. It offers users the ability to remotely visualise their robotic arm in a three dimensional plane, receive status and feedback updates, set the parameters of their operational environment, as well as customise settings such as force, torque, speed and more.

Earlier this year, our Software R&D team collated feedback from customers in order to understand how operators interact with Reach Control in the field. After much testing, we released Reach Control V3.10. This latest version incorporates new features and additions, customer-requested changes and an updated interface design to make operation seamless and intuitive.

FREE UPGRADE FOR EXISTING USERS – DOWNLOAD NOW

Use the password from purchase to upgrade your Reach Control Pro software now! No password? No problem – get in touch and we’ll sort it OR Download the LITE version free!

NEW USER? GET 10% OFF WITH CODE RCP-V3

Quote code RCP-V3 to us at purchase for 10% off the latest Reach Control Pro (Offer expires 30/09/2023).

Among the many features released in Reach Control V3.10, here are the top 5 changes to look out for:

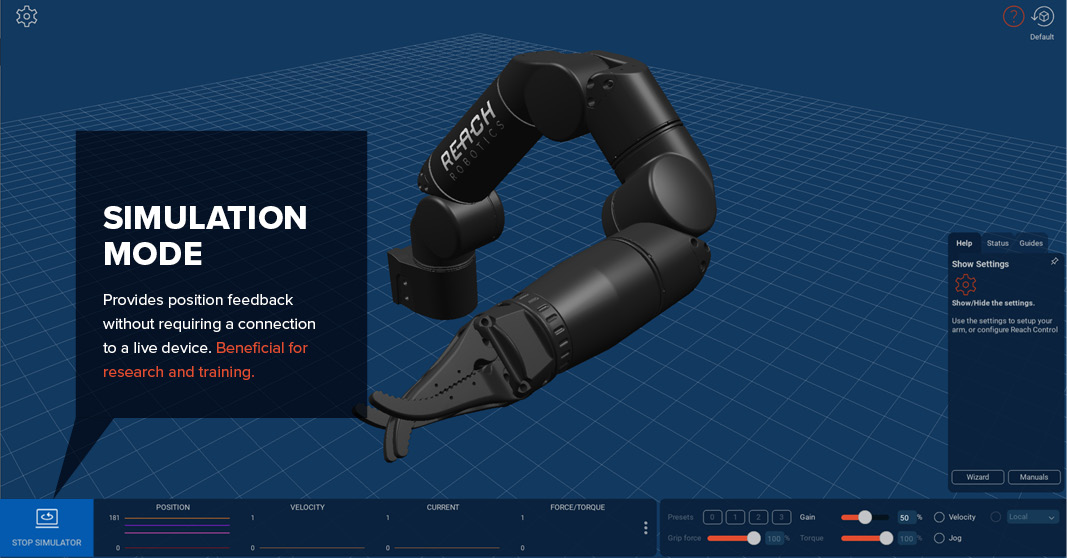

Simulation Mode

We’re introducing a simulation mode with Reach Control V3.10 which provides position feedback from our manipulator technology without requiring a connection to a live device. Use the on screen control arrows or connect a controller to practise or demonstrate how the arm will respond to user inputs. Simulation mode is highly beneficial for operator training and research.

Interactive Tutorials

For first-time users, Reach Control now offers a guided interactive tour through its main features and set-up processes. The tutorial function can be disabled after first use and re-enabled when training new operators.

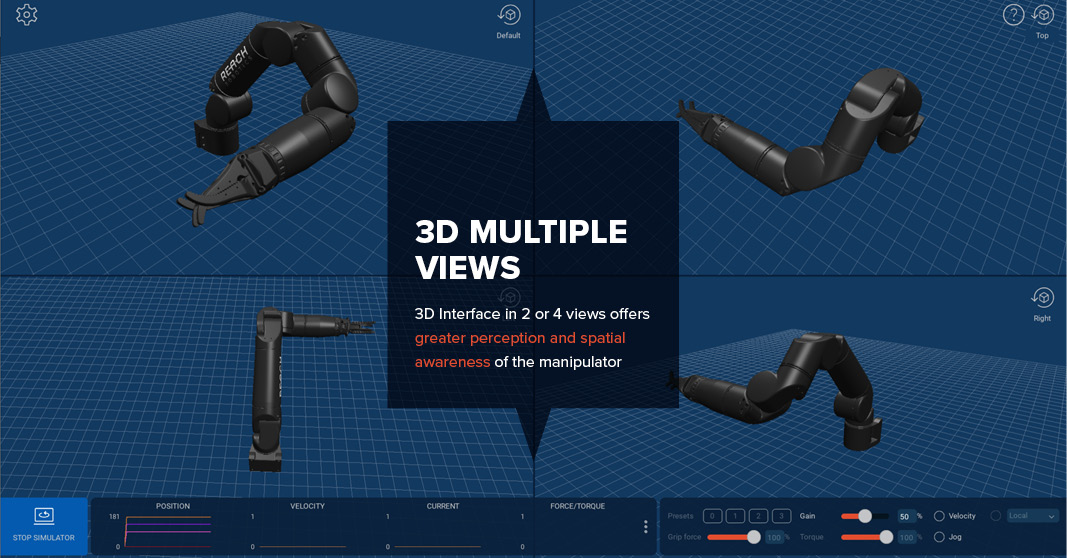

3D Multiple Views

Greater perception and spatial awareness of the manipulator arm is now possible with split screen capability. The 3D interface can be configured in 2 or 4 split views with customisable perspectives such as front, side and top angles.

Keyboard Controls

Reach Control V3.10 enables keyboard control to operate the manipulator – a straight-forward addition prompted by customer feedback. You can map keyboard inputs to each joint of the robotic arm to easily move it to a desired position without having to configure any additional controllers

UI Changes

The traditional Reach Control interface has been redesigned to provide a more seamless user experience. The updated interface is simpler to navigate and live feedback information is easier to discern when a robotic arm is in use.

If you’re interested in further details about the new features and changes to Reach Control software, get in touch with us via info@reachrobotics.com and we can walk you through the upgrade.