NUCLEAR INDUSTRY

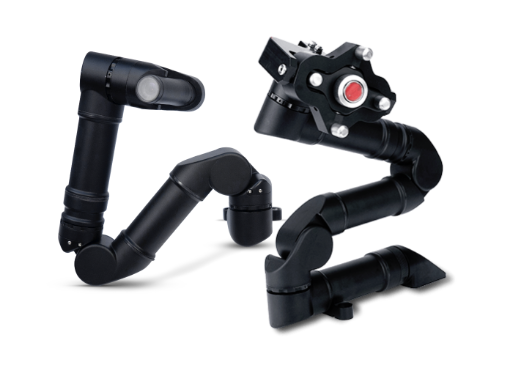

Operate with confidence using bespoke nuclear-ready, lightweight manipulators tested to your environmental specification.

ROBOTIC SOLUTIONS FOR THE NUCLEAR INDUSTRY

The ideal choice for TOPSIDE & Fuel Pond OPERATIONS

- EC Compliant – Ready for CE Marked Systems

- PMUC Compliant Materials (option)

- Stainless Steel Material for Radiation Tolerance (option)

- Radiation Tolerant to at least 400mGy/hr (testing to higher dose rates available on request)

- Cerakote finish for enhanced pH corrosion resistance (option)

- pH tolerant A4 Stainless Steel fasteners

- High dexterity for complex NDT inspections of tanks and pipe walls

- Fully contained system with minimum external fasteners and openings for easy decontamination

- No Earth Metals or Halogens

REVOLUTIONARY ROBOTIC ARMS FOR THE NUCLEAR INDUSTRY

Reduce Mission Time

Conditions

Tools for Accurate Data

for specific requirements

CERTIFIED AND PROVEN

Failsafes, EMC, CE Marking, Gamma Irradiation, PMUC

TOPSIDE APPLICATIONS

Nuclear environments are some of the world’s most hazardous and high risk spaces to conduct inspection and intervention tasks, requiring technology with high reliability and deployment confidence. Our EC Compliant manipulators offer fail-safes, compliant materials and tested solutions in order to maximise safety.

- NDT Inspection

- CVI

- FOSAR

- Welding and Cutting

Have a specific application in mind? Get in touch to find out how we can help.

FUEL POND APPLICATIONS

Our state-of-the-art robotic arms can safely operate in nuclear fuel ponds. Coating options available for high pH environments. Designed to minimise contamination ingress, our manipulators can be integrated with leading ROVs to enable:

- Fuel Rod and Debris Management

- NDT Inspection

- Close Visual Inspection

Have a specific application in mind? Get in touch to find out how we can help.

“Working closely with with Reach Robotics, who have been solving the challenges of dexterity and manipulation in robotics, has led to the signing of a partnership that ensures we continue to collaborate and develop together, while solving both customer and industry challenges with the right solutions. Nexxis plans to integrate the waterproof and durable Reach Alpha 5 arm to a range of crawler systems, which means we can now carry out NDT inspections (UT, ET, ACFM etc) as well cleaning and maintenance requiring complex movements, such as FOSAR operations with precision and ease.”

Jason De Silveira Founding CEO, NEXXIS

OUR CLIENTS IN THE NULCEAR INDUSTRY

MANIPULATORS FOR ALL MISSIONS

Versatile and Effective

PAVING THE WAY

INDUSTRIES WE SERVE

Our manipulator arms and robotic systems enable complex inspection and intervention in mission-critical industries and harsh environments. Discover the domains we operate in: