Reach Robotics’ vision is to extend human reach into harsh environments. We do that with tough, advanced electric manipulator arms and perception systems. A robotic arm, however, is only as useful as its ability to complete meaningful work and so we strive to develop the tooling and software that enables specific missions to be completed successfully and efficiently.

Since 2018, operators within the US Department of Defence (DoD) have used our robotic grabber and manipulator technologies integrated onto their ROVs to push the boundaries of capability with underwater robotic systems. In 2021, we were approached by the US DoD to develop a specific underwater tool that could cut through softlines and conduit ranging from sub-mm to 36mm (1.41”).

With an existing cutter in our Reach Bravo end effector line that was specialised for particular materials, we already understood the technical challenge involved with designing an all-rounder tool that could sever wide-ranging materials underwater. Armed with this knowledge, we got to work with the redesign and delivered a tool that elicited this response:

“The [new] cutter head is awesome! It had no issue cutting through the 1.4” diameter orange cable on the first try. A bonus was that we could actually cut through several lines including 550 cord, Amsteel blue line, a Kevlar line, and several normal boat handling lines.”

~ US DoD Official

Read on for the full story on how we achieved this outcome.

THE Problem

Developing an underwater cutter that works consistently and effectively is not trivial.

Often, if the design is optimized for one type and thickness of material, it is not effective for another. A classic problem, which can seem counter-intuitive, is that whilst you can develop a cutter that can cut through thick and tough cables, that same cutter is likely to be unable to cut through a sub-mm nylon fishing line. Why? Getting the forces and geometries correct, whilst dealing with structural deformation of the cutter under load, is very difficult. As a result, small strands of material can go un-severed.

Indeed, we had released one version of a cutter for the Reach Bravo manipulator system which, while effective in many scenarios, suffered from the problem above in some situations.

The US DoD needed something better. Jean-Eudes Norlain, Mechanical Engineer at Reach Robotics, sought to create it:

“I knew at the outset that optimising our cutter for the US DoD requirements would not be trivial. By far the biggest challenge I foresaw was obtaining the tolerances and accuracy required from the supplier machinists to achieve our idea. We needed to be within one hundredth of a millimetre on some complex shapes. If we couldn’t achieve this, there would be no point re-designing at all.”

DEVELOPING A Solution

Jean’s approach was to begin with a core assumption: If the blades maintained contact throughout the full cut, then the only limit to cutting ability would be the force produced. Any amount of blade separation allows for a recess in which material can hide and escape the cut.

He then identified the key shortcomings in our existing cutter design:

- The jaws had the ability to bend slightly, causing separation under load,

- Components in the assembly, such as the shaft and retention pin, would also bend slightly under load,

- The blade angle could not be sufficiently finely tuned to achieve the required interface angle,

- Ill-defined tolerances for some components meant that that the manufactured product had too much play, and

- Poor grabbing ability: the tool should also allow users to choose to grab, not cut, an object.

He also needed to work within constraints such as:

- Not introducing too much friction into the assembly in pursuit of constant blade contact, and

- Ensuring manufacturability and ease of assembly by the production team.

As with all developments at Reach Robotics, Jean pursued the optimal solution through a rapid and continuous design-prototype-evaluate approach. He produced three successive prototypes before he was comfortable that the overall requirements of the cutter had been achieved.

“We realized that it would be important to design around a COTS [Commercial-Off-The-Shelf] blade set to enable easy maintenance worldwide. However, designing around a COTS product is not without challenges and design constraints.”

Jean-Eudes Norlain

Jean resolved the shortcomings of the original cutter and introduced new features with some clever design work. Specifically:

- Improving the blade positioning methodology, allowing the insertable COTS blades that sit in the jaws to be tunable within 0.02mm accuracy and without creating excessive friction,

- Maximizing the stiffness of the cutter through an increase to cross-sectional area and a thicker drive shaft, – Reducing weight by introducing a singular jaw part with no fasteners,

- Improving corrosion resistances by using 304 Stainless Steel, and

- Introducing topology optimization to maximize the stiffness-to-weight ratio on the whole assembly while preserving lift and payload capacity.

Further, the integrated grabber functionality was optimized by implementing:

- A triangular teeth mesh made from 304 Stainless Steel and tempered for maximum hardness,

- A teeth topology that provided anisotropic friction coefficient (simple terms: object can slide deeper into the jaws but not out), and

- The gripping plates are swappable inserts to allow for routine servicing.

Here’s the result:

“I’m proud of the resulting product because it is multi-functional (combining gripper and cutter) and removes the issues we saw with other cutter designs. I’m also proud that we succeeded in bringing a novel topology optimization methodology into our design process which will be used in future Reach Robotics technology. For example, the same technology has now been used to optimize the design of the Reach Bravo pressure housings.”

Jean-Eudes Norlain

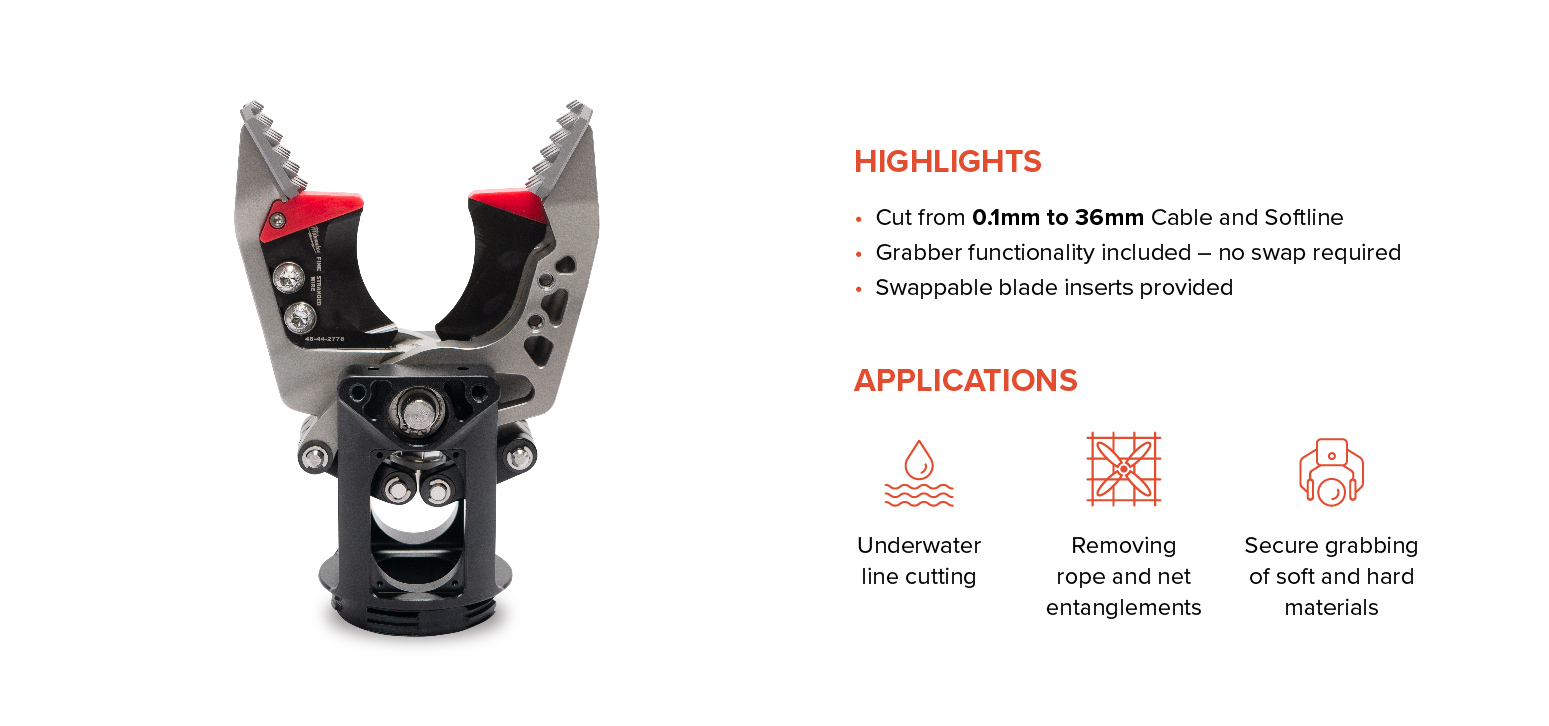

This cutter, available as Part Number P/N RB-1042 on all Reach Bravo systems (grabbers and manipulators), is the most effective electrically actuated cutter for inspection class ROVs. Purchase one today to enable cutting through conduit cable (including with Kevlar shielding) as well as very small Dyneema and nylon softlines.

Need a cutter or have a different tooling requirement? Tell us about it today.

This article has been approved for release by US Department of Defence (DoD). Names of US DoD officials have been omitted for privacy.