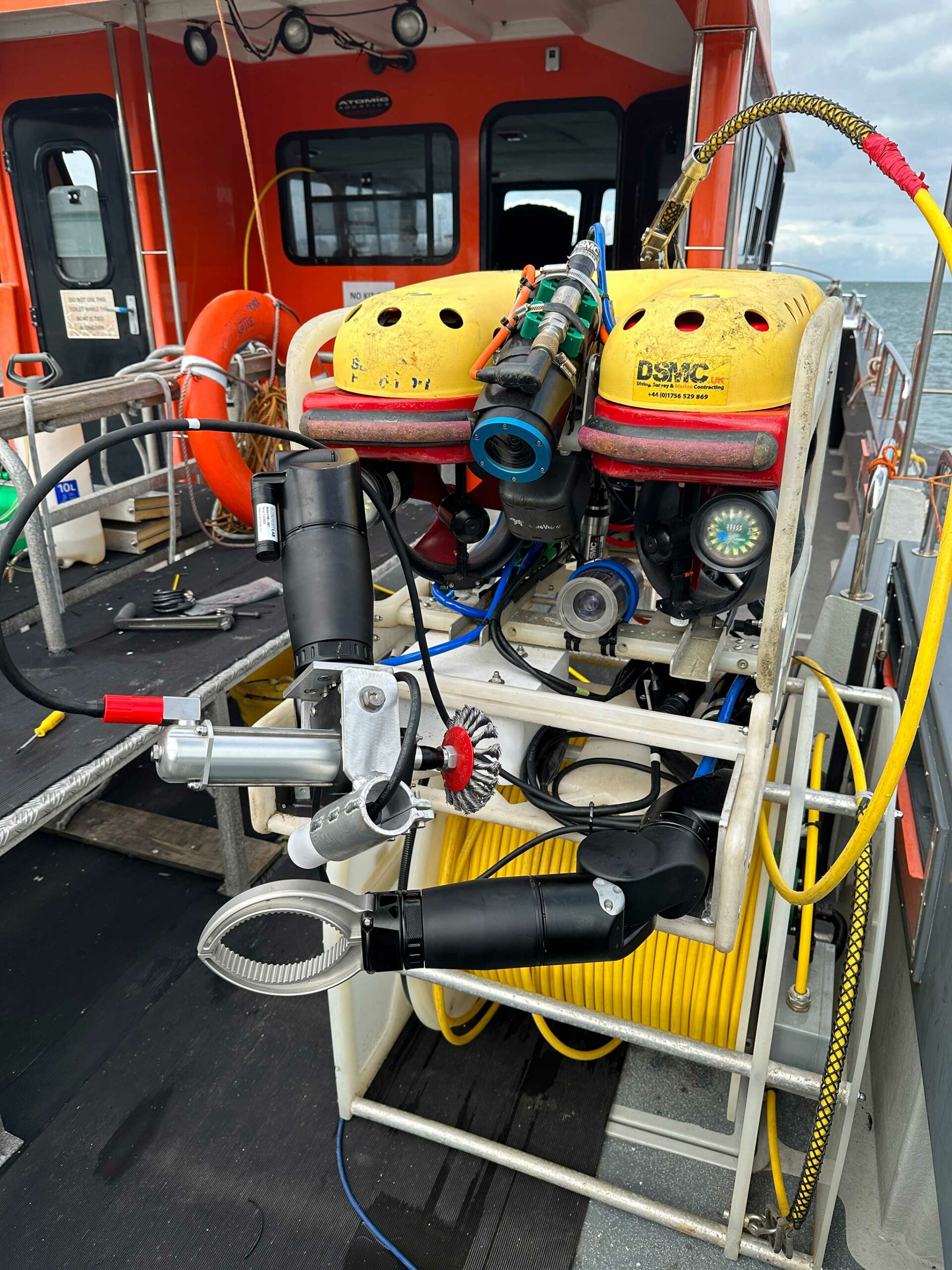

Earlier this year we received a first hand account from Charlie Bayston, Managing Director of Diving Survey & Marine Contracting (DSMC) about their work on a sensor removal project using Reach Robotics manipulators (Missed it? Catch up here). As a specialist marine service provider, DSMC offer commercial diving, hydrographic survey campaigns and conduct various missions requiring remotely operated vehicles (ROVs). Their subsea services regularly call for intervention in inaccessible or high risk scenarios, driving them to pioneer the use of robotic manipulators for inspection applications including capturing Ultrasonic Wall Thickness (UT) and Cathodic Protection Potential (CP) measurements. Since 2021, DSMC have trusted Reach Robotics’ advanced manipulator systems to get the job done.

Recently, we heard from Charlie again with a second account detailing DSMC’s followup to their initial sensor recovery success using Reach Bravo manipulators. This time, they were aiming to clean bio-fouling and take CP readings from riser pipes completely diver-less, with their SAAB Seaeye Falcon ROV. Here is Charlie’s first-hand take on this project, detailing how DSMC are using robotic manipulators to change the remote operations landscape:

PIPE CLEANING AND CP MEASUREMENTS: FIRST-HAND FROM CHARLIE BAYSTON, MANAGING DIRECTOR OF DSMC

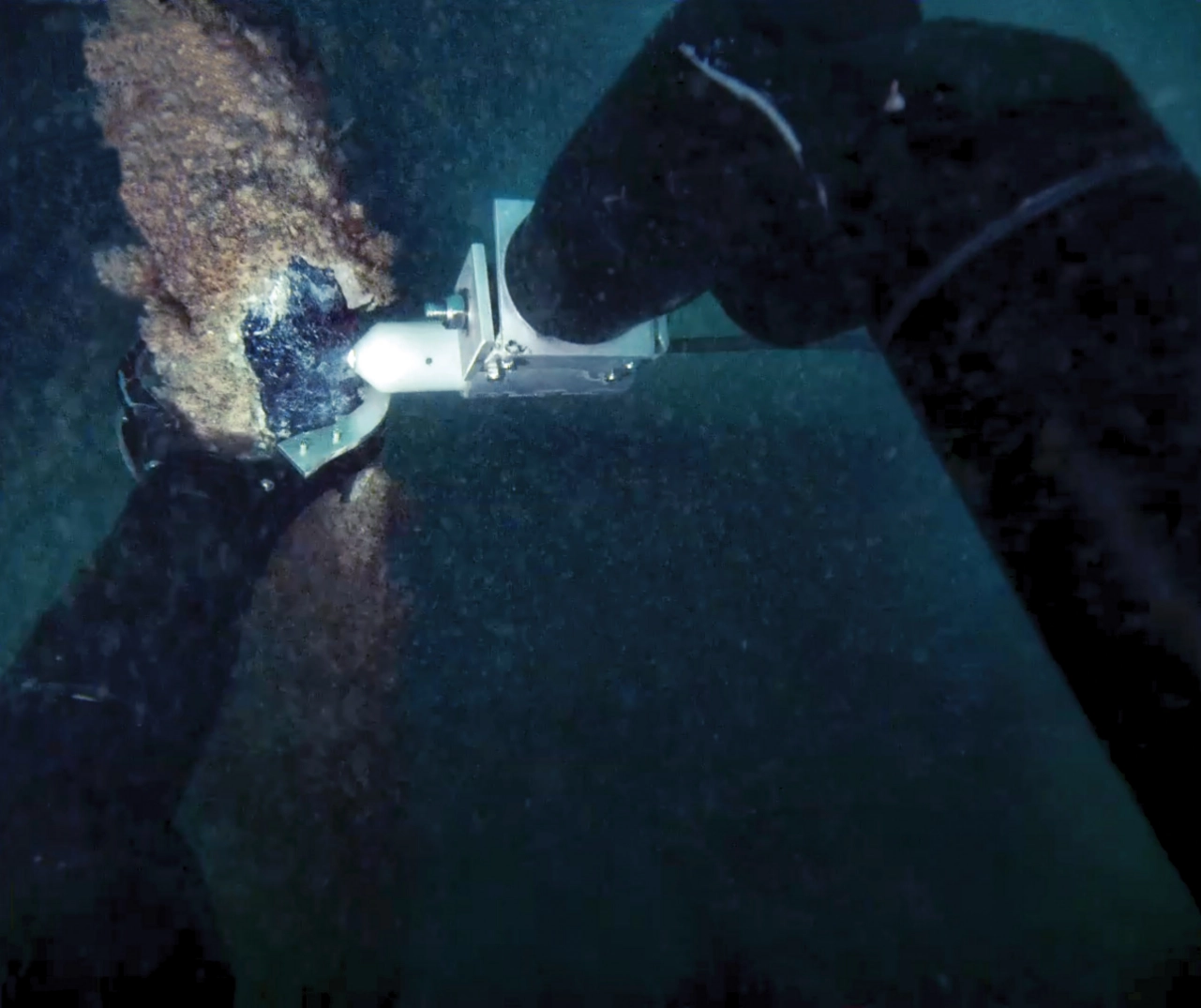

Following [the sensor recovery project] we realised there was a lot we could achieve with Reach Robotics technology. Another client asked if we could investigate alternative methods to take CP readings from calcite-covered riser pipes in 30m of water. A task we normally undertake annually with divers. The pipelines have an impressed current system which cause a hard calcite shell to form. A diver is normally required to remove the calcite exterior with a chipping hammer.

DIVER-LESS SOLUTION

Aiming for a compact ROV solution, we purchased a Reach Bravo-3 with Stainless Steel ‘Mega’ jaws that looked like the perfect tool to grasp the riser pipes. We also selected several tools to trial removing the hard calcite: an electric rotary brush, a pneumatic needle gun and some serrated teeth for bolting to the jaws of the 1kN grip-force, Bravo-3 manipulator.

We fabricated a mounting bracket that connected to the Bravo-5’s Payload Interface accessory. The primary plan was for the Bravo-3 to grip the riser pipe, stabilising the ROV in the tide, while the Bravo-5 cleaned the calcite off a localised area and captured CP readings without requiring tool changes.

GAME-CHANGING RESULTS

The result of the trial was surprising. Rather than removing the calcite, the rotary wire-brush polished it to a smooth finish. Next, we trialled the pneumatic needle gun but it couldn’t achieve the required pressure to operate properly. Finally, the serrated teeth on the ‘Mega’ jaws combined with the Bravo’s high grip force worked fantastically to crack and scratch the calcite shell off to expose clean steel.

Having established a successful cleaning method, we removed the calcite and took readings from all eight risers in one tidal window. We are extremely impressed by the result, especially with this class of ROV being enabled to provide such a solution. The Reach Bravo manipulator has fundamentally changed how we operate and the future of our work.

MAKING IT POSSIBLE – THE REACH BRAVO HUB

With our Reach Robotics tooling increasing, we purchased the Bravo Hub to allow us to easily power, add and remove items with minimal reconfiguration time. Our Falcon is limited to one ethernet port on the multiplexer and very little space in the VJB to accommodate additional devices. The Bravo Hub contains a subsea switch allowing us to run multiple ethernet devices on the machine simultaneously. We also own a Hydro-300 photogrammetry system for underwater 3D modelling requiring gigabit speed, and a 24V ‘Orphie’ low-visibility IP camera. The team at Reach made some custom modifications to our Bravo Hub, increasing the speed of the switch to Gigabit and giving us both 24V and 48V outputs; this sort of collaboration has certainly set Reach Robotics apart as a supplier.

With the Bravo Hub and tooling skid we now run our Blueview sonar, Orphie camera, Hydro-300 Photogrammetry camera, the Bravo-3, Bravo-5 and its accompanying IP wrist camera simultaneously up to gigabit speed.

For a confidential conversation about Reach Bravo’s suitability to your specific requirements, contact sales@reachrobotics.com

For more information about DSMC, visit: www.dsmc.uk.