Reach Robotics has been producing subsea manipulators since 2017 for defense and commercial clients all over the world. Since the release of our first product, the Reach Alpha Dual Function Grabber, our manipulators have grown in complexity and capability. Along the way we have learnt important lessons about developing and producing advanced, underwater robotic systems and have gained a better understanding of our clients’ needs and vision.

When we embarked on the design of the next generation of subsea manipulators all of the lessons and feedback from defence and commercial operators were used as the basis for the Reach X Advanced Intervention System (RX-AIS) specification.

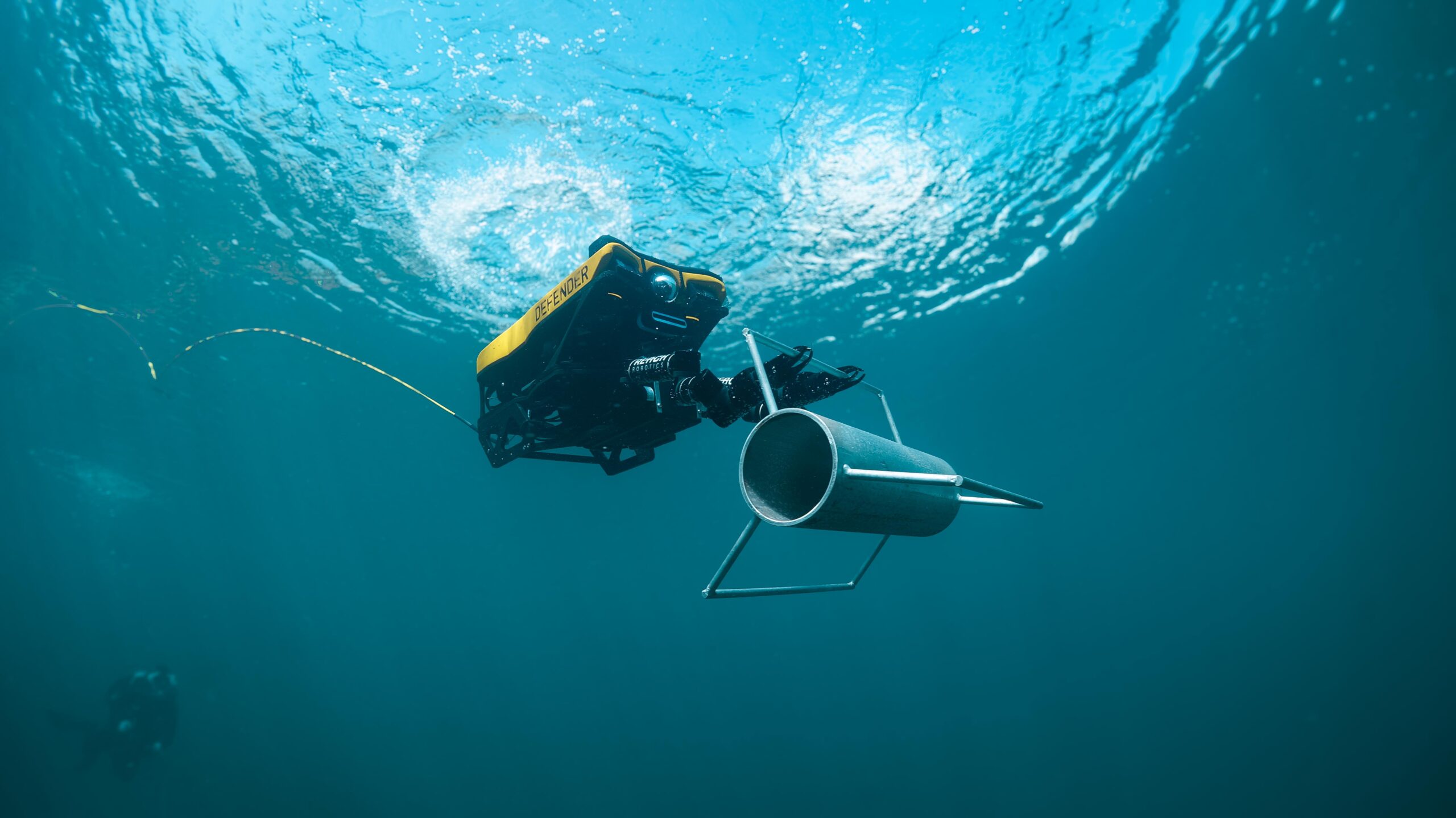

The Reach X AIS is designed for mission critical scenarios. Unpredictable environments, life threatening situations and time-critical deployment all make up the operational intent of this solution. Human clearance divers will always be needed for complex tasks but there are both mundane and dangerous tasks which the RX-AIS was designed to address. The aim: to get the diver out of the danger zone without compromising mission success.

This is of course easier said than done.

What’s significant about the RX-AIS?

Dexterity

One of the immediately noticeable features of Reach X AIS is its dexterity in relation to its size. Never has an arm this dexterous been available in so compact a form for portable ROVs.

The manipulators are both seven function, six degree-of-freedom manipulators with each axis capable of full, continuous rotation. This expands the useable workspace and the ability to manipulate objects within that workspace. The reach of the manipulators – 500mm – was selected based on calculations of what would most effectively cover the desired workspace for a portable ROV, without increasing the risk of self-collision (an arm too long ceases to be useful close in to the vehicles workspace). Onboard kinematics computation make end-effector control effortless; as an operator you ‘fly’ the jaws or tool where you want and the joints of the manipulator do the rest.

Performance

The performance of Reach X AIS is unparalleled. It has a 6kg lift capacity (3kg each arm) at full reach while weighing less than 5kg in water. Its 120deg/s max speed makes the manipulators feel responsive and enables adjustment in the face of underwater motion. What’s important here is that the manipulators could lift enough within the capability of a portable ROV. When lifting anything over about 10kg, the fly-ability of the ROV becomes the main factor, not the manipulators. Additionally, the need to have sufficient torque in each joint to enable turning of tooling against resistance was a key design requirement.

Deployability

The 50mm (2 inch) diameter and 500mm length were designed for a compact stow position, folding neatly under or next to the host vehicle when attached to an easily removable skid. These features make this manipulator system an incredibly versatile tool for intervention and inspection without hindering vehicle performance or increasing the operational footprint. As a system designed to be rapidly deployed and recovered over the side of a variety of naval vessels, it was important that the system was practical, comfortable and safe for operators to use (e.g. minimizing back strain to operators and being transportable through narrow confines of a surface vessel.)

Reliability and serviceability

Ensuring the RX-AIS can be depended on for mission success was a huge factor in the design. The system makes use of a new sealing innovation which drastically reduces the chance of a leak while maintaining oil free operation. In the event of a joint failure a single spare can be used to swap out the broken module in a matter of minutes without special tools or training. Common joint architectures mean that with a few different spare joints, all joints of the manipulators can be replaced. This feature reduces the cost of holding a full system spare and allows for on-the-fly configuration changes to be made if necessary.

Control and Interface

Operator input can take several optional forms. One is via dual, compact, 6 degree of freedom hand controllers (we call them ‘command pods’) that sit on the side of the ROV control interface. Alternatively, the system can be controlled with mimic controllers whereby the operators control of these mock arms is mirrored on the vehicle’s manipulators. The decision on control type is up to the client, with preferences generally depending on the operating environment. The mimic controller is perhaps more immediately intuitive and useful if you have a very stable operating platform. Conversely, the ‘command pods’ are very attractive because of how small they are and easy to grab/let go during operations.

Schedule a call with us to learn more about how your operations can be transformed with the Reach X Advanced Intervention System by emailing sales@reachrobotics.com. Alternatively, request a free quote and let us know a bit about what you’re aiming to achieve.